1. Clean the ground and find the center line: First, clean the ground slag, and then find the center of the room with a measuring tool, draw the center cross line, and ask the cross line to be equally divided vertically.

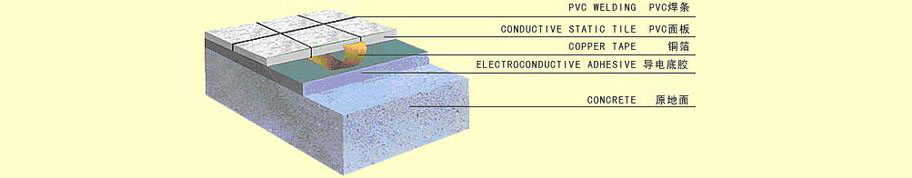

2. Laying copper foil (or aluminum foil) network 100cm*100cm; a. Paste copper foil strips on the ground according to the specified size to form a mesh. The intersection of the copper foil should be bonded with conductive glue to ensure the conduction between the copper foils; b. At least four points per 100 square meters in the pasted copper foil network are connected to the grounding wire.

3. Laying the floor: a. Use a scraper to smear part of the conductive glue on the ground first. Due to the particularity of the conductive material, it is recommended to use special conductive glue; b. In the process of laying the floor, it is necessary to ensure that the copper foil passes under the floor; c. Use a welding torch to soften the electrode at high temperature and weld the space between the floor and the floor; d. Cut off the protruding part of the electrode with a knife to complete the entire ground construction; e. During the construction process, a megohmmeter is often used to test whether the surface of the floor is connected to the copper foil. If there is no connection, find the reason and re-paste it to ensure that the surface resistance of the floor is between 106-109Ω. f. After the floor is laid, the surface must be cleaned.

4. Maintenance: a. Do not scratch the floor with sharp hard objects and keep the surface smooth; b. When cleaning the floor, scrub with a neutral detergent, rinse with water and dry, then apply anti-static wax.

Post time: Jan-20-2021